CFP Forging Capabilities

Cerro Fabricated Products, a leading forging company, has truly taken the art of closed die hot forging and turned it into a precise science. Here at our facility, we have more than 30 forge and trim presses at our disposal, giving us extensive in-house capabilities.

Our expert team is able to create precision forgings with near-finished dimensions to reduce final machining time and minimize waste. Plus, our forgings have grain structures that are superior to the original billet for enhanced strength and performance. As a result, we offer our customers components at a lower overall cost.

We use D-Form simulation software to experiment with different die designs to optimize material flow and metal utilization prior to creating our final production dies. In addition, we have in-house fluid-penetrant testing (FPT) equipment to maintain the highest standards of quality throughout the manufacturing cycle. Notably, we perform CMM dimensional checks in-house to confirm that all of our forgings are within dimensional tolerances throughout the entire production run.

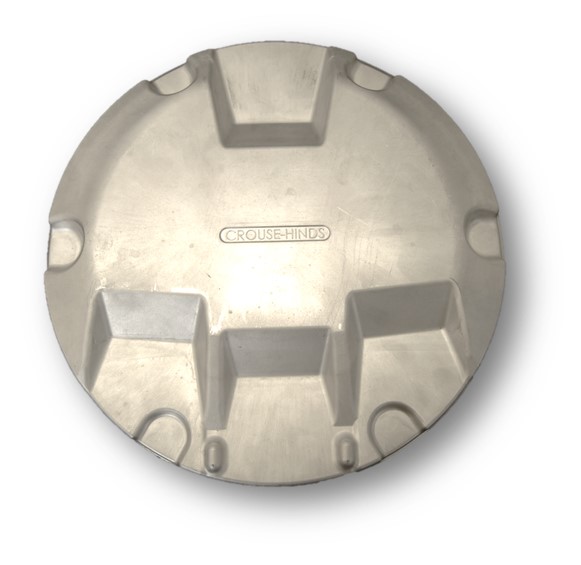

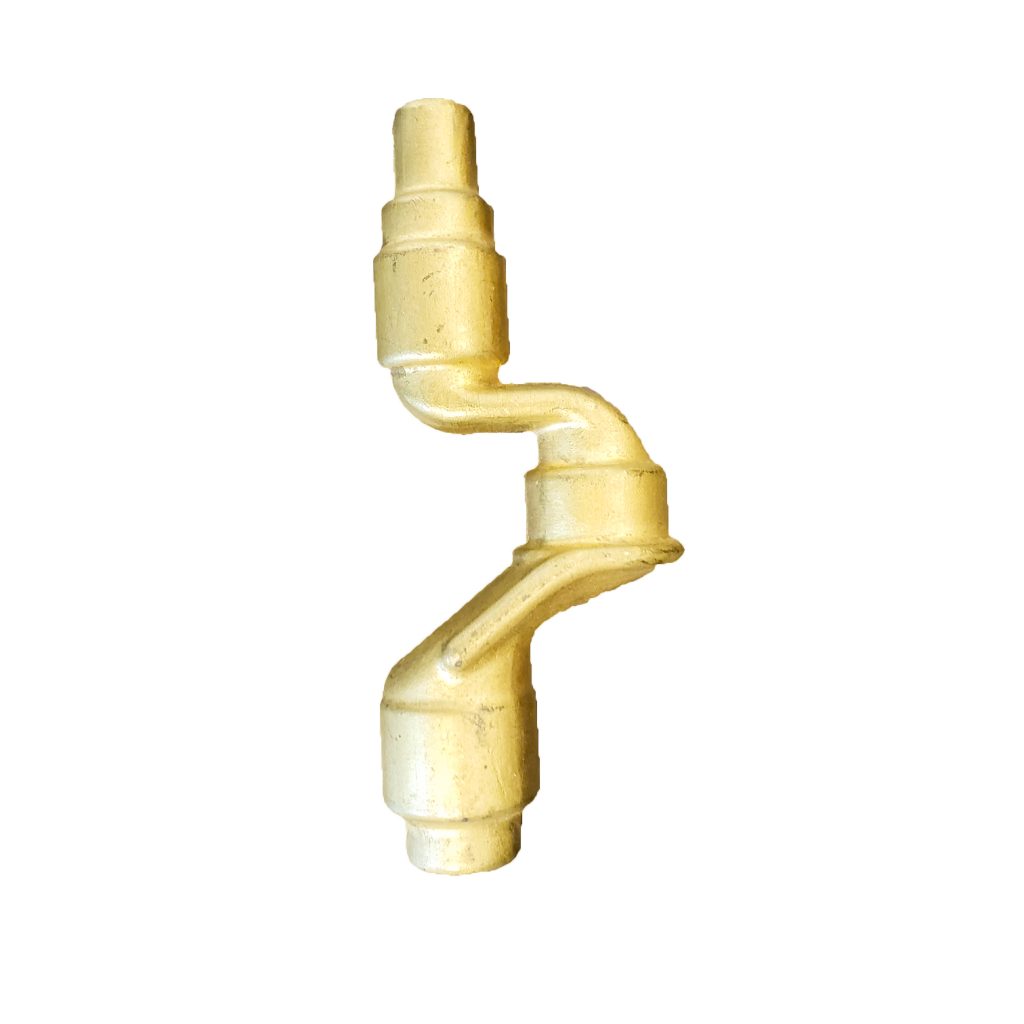

Learn more about our aluminum, brass, and copper forgings and our markets served. See below for a short demonstration video of the closed die forging process and our gallery of forged components.

Forged Components Gallery