Benefits of Forged Aluminum & Brass vs Billets to Forging

These are many benefits to choosing forged aluminum and brass rather than using billets:

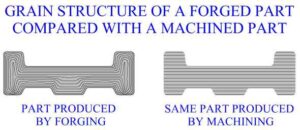

- Forgings are grain-oriented to the parts’ external contours for improved mechanical properties resulting in stronger, improved fatigue resistance and less susceptibility to stress corrosion cracking.

- Forgings yield lower scrap and increase efficiency of production, a cost differentiator in high volume applications.

- Forgings require fewer secondary operations since the parts are produced to a closer net shape.

- Preferred draft is 3° or more per side to allow a part to be successfully removed from the die without damage to the part or die. Less draft may be allowed, depending on part geometry.

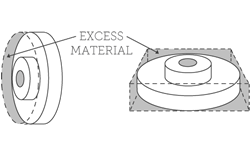

- Stock will be left on all machined surfaces to allow for industry standard forging tolerances. The amount of stock is specific to the part geometry but normally is .050” per side.

- Fillets and radii are required on all forged contours to promote good material flow and extended die life. The more generous the radii, the more both of these aspects are improved. Preferred MIN radius is .080, but this can be reduced in certain alloys and part geometry.

- Machining fixture design is based on part geometry. When reference is to the center of the forging, a self-centering vise is preferred. When reference to a surface datum is required, a fixed jaw vise is used.

- The most efficient way to minimize cost is to leave as much surface area on the part “as forged” as possible.

- Because there are tooling costs associated with forgings, higher volumes are the best way to offset the cost of tooling. Please consult your Cerro sales person for the best fit quantities for your specific project.