Tool and Die Manufacturing Capabilities

Before a part can be forged, tooling must be manufactured. One of our core competencies at Cerro Fabricated Products (CFP), an aluminum forging company, is our tool and die manufacturing. We develop and maintain tools and dies in house for non-ferrous forgings without the assistance of outside vendors.

Additionally, we develop precision tooling and dies to forge many parts, within size parameters, at net or near-net shape to precise tolerances. We ensure that we control the quality, accuracy, and cost of our tooling in-house.

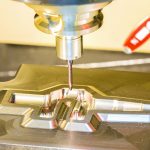

Cerro manufacturers forge tooling, trim tooling, and machining fixtures in-house from high-grade tool steels. Our shop uses state of the art CNC lathes, sinkers, and wire EDM machines to make dies to world-class standards.

We understand that working with a customer early in the part design stage is important for die life. By aligning the design process with customer needs, Cerro optimizes die performance and longevity, thereby minimizing the risk of premature wear and damage. This encompasses consistent part quality throughout the entire production run.

Our primary objective is to uphold the integrity and functionality of the tooling required for production demands. Each month, Cerro allocates dedicated time within our tool and die schedule in order to strategically budget our resources to facilitate the timely sampling of new parts.